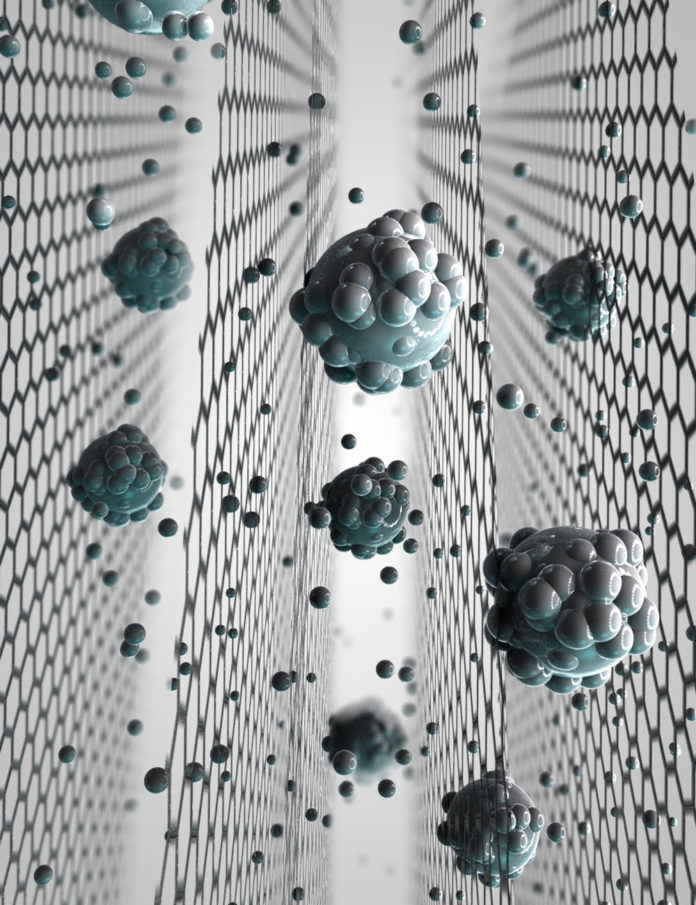

Graphene is a form of carbon. In the past, scientists used single-layered graphene in the desalination process to separate water molecules from those of dissolved salts. The procedure was expensive because getting hands on graphene was costly and ineffective because scientists had to drill holes into the layer to make the sieve. The holes would always turn out to be much larger than was required so the entire water mixture would make its way through the sieve.

To combat that, scientists turned to graphene-oxide. After all, it was easier to oxidize graphene in a lab that to hammer it into a thin layer according to Professor Rahul Nair. Nair led the latest venture into the uses of the graphene oxide membrane. Scientists rejoiced when the graphene oxide membrane could split water-oil mixtures. When they tried the membrane on water-salt mixtures, though, the membrane was not up to the task.

After multiple studies based on their lab work, scientists from the University of Manchester in the UK now think they’ve found a way to revolutionize graphene-oxide membranes so that they can even separate salt molecules and water molecules.

How did they do it?

In their publication in the Journal of Nature Nanotechnology, the researchers revealed that the key to their findings was in finding a way to control the size of the membrane’s pores. Doing so may sound easy, but it is not.

Studies conducted in the past had one problem when it came to making graphene-based barriers sieve salty water. Each time the membrane was placed in water, it swelled. Swelling increase the size of the membrane’s holes thus allowing both water and saline molecules to pass through. In short, the membrane was useless in desalination.

To combat this little snag, Nair and his team lined both sides of the membrane with epoxy resin. The resin comes from the bluegum and is mostly utilized in making glue. The resin made the membrane turgid or stiff so that the membrane did not increase in size after submersion in water. Modifying the membrane enabled them to control the size of the pores, the researchers wrote.

When a solute such as salt dissolves in water, its molecules surround themselves with a ‘shell’ of water particles due to chemical bonding. Nair explained that while individual water molecules could pass through their manufactured membrane, a salt molecule and its host of water ‘shells’ could not. As such, the membrane could separate lone water particles and leave behind the salt residue.

Nair and his team also reported that the membrane allowed water to seep out faster than its predecessors. Nair remarked that the pressure from the side of the membrane with the salt particles forced the water molecules on that side to pass through the membrane in a single file ‘like a train.’

The Implications

Nair and his group were excited by their findings. “Being able to separate water and salt on an atomic scale is a huge step forward. We are confident that although our model is lab-produced, it can be scaled up and mass produced for use in massive desalination projects.”

The question of the membrane’s durability remains, but Nair and his team may have brought the world closer to dealing with water scarcity by harvesting from a vast resource: the world’s oceans.